Battery Energy Storage Systems

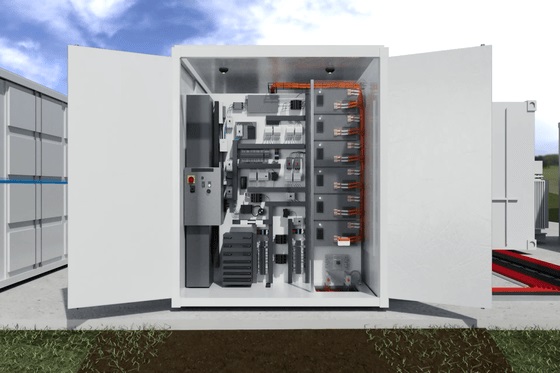

Build and deploy safe, reliable, and intelligent energy storage.

Our UL Listed components help you demonstrate the highest level of quality to earn Battery Energy Storage System (BESS) project preference.

Build in Performance

Innovative technologies are best built on proven experience. Use our control panel expertise to optimize valuable Battery Management System (BMS) enclosure space and solve the toughest noise, environmental, safety, security, and connection challenges.

Build with Panduit

Proven Reliability

Build a UL Listed BMS enclosure with our comprehensive line of UL control panel products.

Simple Sourcing

We’ll help you choose from our 30,000 readily available components to bring your design to life.

Uncompromising Safety

Deliver the highest level of safety with cable cleats, labeling, and innovative Verisafe™, solutions.

Panduit Solutions for BESS

Product Highlights

Cable Cleats

The best way to secure large cables necessary for utility scale storage, because in the event of a short circuit fault cleats also keep cables safely contained to prevent harm to people and property. Panduit offers three types to fit any BESS installation, all tested to IEC 61914, the globally recognized standard.

PanelMax™ Duct

Want to optimize space within your BMS? Our patented Corner and DRD din rail wiring duct can exploit previously unusable areas within the panel cabinet, reducing the overall footprint up to 30%, with less required material and faster installation. Also available in shielded versions to help you solve the toughest noise challenges for upmost reliability in the field.

Power Connectors

We offer power connectors for every aspect of BESS, from small terminals in the BMS, to large aluminum lugs for connecting into power infrastructure. For high-power, harsh environment battery energy storage applications, we recommend Pan-Lug Compression Lugs. Tin-plated to inhibit corrosion, they feature a flared barrel for easy wire entry and install simply and securely with a crimp tool.

Wire Identification

Our identification solutions simplify every stage of BESS, from assembly to installation and maintenance. Labels can be printed on desktop or handheld devices to maintain legibility, whether in the factory or the field. Choose self-laminating wire labels for fast installation with long term durability and turn-tell labels for high-density cable applications within the BMS.

Wire Basket

Rely on our overhead cable tray routing system to manage connections between the BMS and the Battery Stacks. This next-generation system is up to 20% lighter, with a greater load carrying capacity, for a superior strength-to-weight ratio. It’s designed to install smoothly, using larger openings to reduce cutting during sweeps by up to 50%. Plus, it’s made with at least 70% recycled steel.

Latest From Panduit Blog

- Item 3

- Item 1

- Item 2

- Item 4

- Item 5

- Item 8

- Item 6

- Item 7